Guide des bagues de skateboard

Here you'll find everything you need to know about skateboard bushings:

Choosing the right bushings often presents a dilemma not only for skateboard beginners, but also for experienced skateboarders and professionals who experiment with their equipment from time to time to find the perfect setting for themselves.

As with almost everything in skateboarding, there are no rules here; it's about body weight, intended use, and above all, personal preference .

Even pros ride their trucks with settings ranging from super soft to super hard. Daewon Song is known for setting his trucks so loosely that he only uses one rubber pad on his front truck instead of the usual two. He grinds down the rubber pads on his rear truck to make them smaller and give the trucks more play. This is unthinkable for a ramp skater like Danny Way, who needs super-stiff trucks for stunts like jumping over the Great Wall of China to even be able to stay on course at such high speeds.

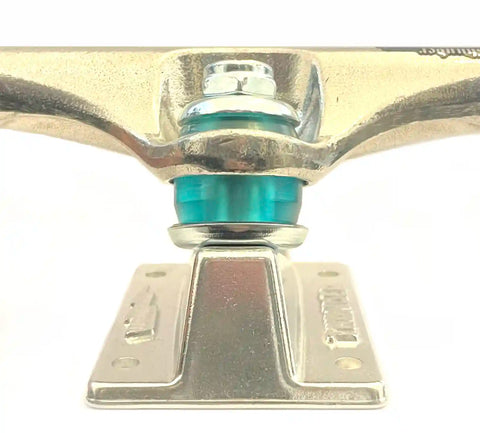

Skateboard bushings, like the wheels, are made of urethane. The range of available hardnesses extends from approximately 78A to 100A, with 78A being considered very soft and 100A very hard.

New trucks typically come with medium bushings , meaning they have a medium hardness. Established brands like Independent, Thunder, or Venture, for example, ship their trucks with 90A bushings. This is optimal for most skaters.

As mentioned before, you will find out for yourself which hardness is right for you during your skateboarding career.

For skateboard beginners, here is a list of the optimal hardness levels to start with:

For children or lighter skaters up to about 40 kilos, we recommend rubbers with a hardness of 78A to 88A.

Bushings from 40 to 80 kilos with 90A to 92A.

For body weights of 80 kg and above, hard steering bushings with a rating of 94A to 100A are suitable.

Which bushings fit my trucks:

Even though there are many suppliers of bushings and most skateboard truck manufacturers offer their own replacement bushings, you don't need to worry about buying the wrong ones. The size of the bushings is largely standardized, and you can screw bushings from any brand onto your trucks. So, for example, it's no problem to screw Independent bushings onto a Thunder truck and vice versa.

The inner diameter of steering bushings is determined by the kingpin at 10 millimeters; the height of the upper bushing is usually 12 millimeters, and that of the lower one is 14 millimeters.

Bushings squeaking:

New steering bushings, especially those not yet broken in, can squeak. This is perfectly normal and usually decreases the longer you drive with the axles. However, the squeaking might never completely disappear. If it bothers you, adding a drop of ball bearing oil between the bushings, the axle hanger, and the washers will help.

If the board is not moving straight, or pulls to one side:

First, you should rule out other factors that could cause your board to pull to the left or right when pushed without weight. A warped deck, broken bearings, a broken pivot cup, or even a bent truck could be the cause. If none of these apply, it's most likely your bushings. New bushings, especially those not yet broken in, tend to stick slightly when the truck is unloaded. This usually resolves itself over time. But don't worry, as soon as you put even a little weight on the board, it will behave completely normally when steering.

You can find our entire bushing range here: